Offer on-site machine tool for calibration and volumetric error correction services by obtain accurate information related to path tracing and measurement such as robot arm, CNC machine etc.

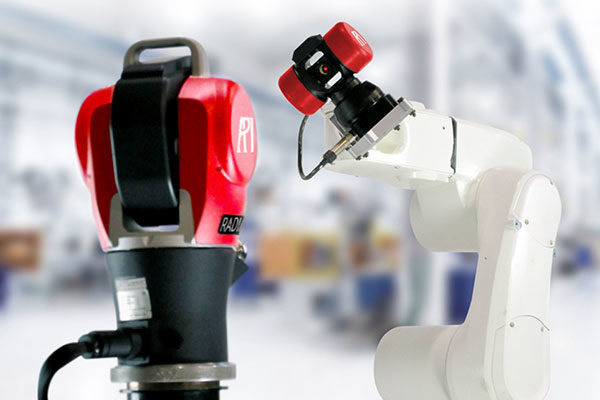

Combined use of laser tracker and STS (Smart Track Sensor) reveals real time position and orientation of a moving target like a robotic end effector or CNC machine cutter. The STS continuously locks on to Radian Laser Tracker to determine position (x, y, z) and angular orientation (pitch, yaw, roll) of a tracked point in real time. Equipped with Robot Performance Measurement and Spatial Analyser software, we can provide the following services:

- Robot calibration

Procedure uses ISO 9283 guidelines to check accuracy, repeatability, pose, distance, drift, overshoot, path by exercising all robot joints. This helps to reduce inaccuracies and provide performance data during Robot Calibration. It will ensure your equipment accurately display and produce precise measurements with repeatability in manufacturing tasks.

- CNC Machine calibration

Ability to track the machine’s tool-tip location throughout the entire machine volume by measuring all 21 error parameters for 200–400 locations during extensive axial movements. Each generated point is an accurate reflection of the machine’s kinematic errors; a software algorithm extracts error sources and builds an accurate volumetric map providing compensatory values as an adjustment to offset for the inherent machine geometry errors.