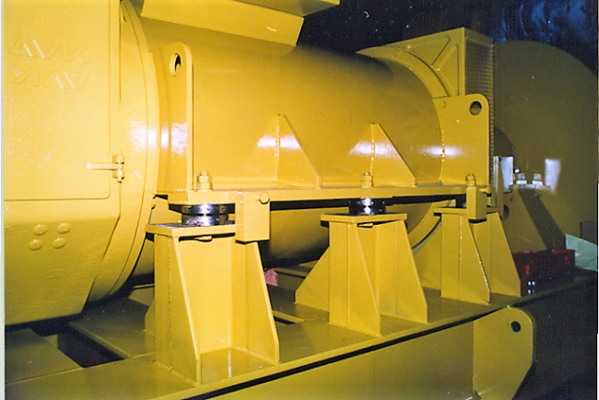

The SKF Vibracon chock is a versatile, adjustable steel chock that offers a superior alternative to traditional rigid steel chocks, shims, or epoxy resin chocks. Its innovative design allows for re-adjustment, enabling precise alignment of machinery throughout its lifetime.

Benefits of Using SKF Vibracon:

- Eliminates soft foot problems:

Whether dealing with twisted skids or unmachined bases, Vibracon ensures parallel and angular alignment. - No base frame machining required:

Save time and effort by avoiding unnecessary machining. - Re-adjustable:

Vibracon can be reused and adjusted for realignment, extending its lifespan. - Faster alignment with laser equipment:

Reduce alignment time by up to 50% when combined with laser alignment tools. - No curing time:

Unlike epoxy resin chocks, Vibracon doesn’t require curing, speeding up the process. - Time-efficient installation:

Avoid the time-consuming fitting of rigid steel chocks. - Dry dock installation:

Chocking can be completed while the ship is in dry dock, with alignment checks and adjustments performed after launch. - Minimal foundation machining:

In most cases, only local machining (where elements are fitted) is necessary. - Reduced chocking time:

Vibracon speeds up the installation process. - Easy installation:

No special skills or tools are required for installing SKF Vibracon chocks.

For more information on our rotary equipment alignment solutions, visit our dedicated page.