Customer's Challenge

An offshore floating structure in Panama required a critical component replacement to maintain operational status. The new part was being fabricated in Europe and shipped to the site for installation. However, the component was connected to three welded pipe joints, making the exact measurements of the x, y, and z axes between the flanges critical to ensuring a seamless fit. Inadequate measurement tools like tapes had previously led to on-site fixes such as grinding and rigging, which resulted in significant downtime and costly last-minute modifications.

Solutions

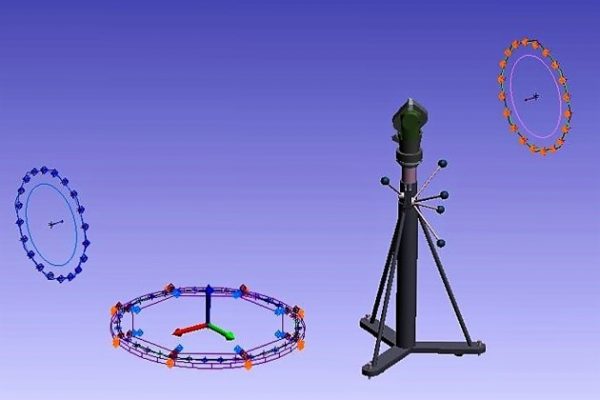

Given the tight geometric dimensioning and tolerancing (GD&T) requirements and the space constraints on the floating structure, Metal Machines deployed a senior technician equipped with an API Laser Tracker. This laser tracker, known for its compact size and portability, was ideal for offshore use. By using Spatial Analyser software, which connected to the laser tracker, our technician was able to capture highly accurate 3D measurements and present various graphical views in real-time to discuss with the site representative.

Benefits

The entire project was completed within two days, achieving a 100-fold improvement in accuracy compared to traditional measuring tape methods. The laser tracker captured not only distances but also the Pitch Circle Diameter (PCD) of the bolt holes, bolt orientation, flange surface flatness, and other critical dimensions. These precise measurements helped the client ensure that the new component met the GD&T requirements, preventing costly, last-minute site modifications. As a result, the project was completed on time and within budget, reducing downtime and logistics costs.