Customer's Challenge

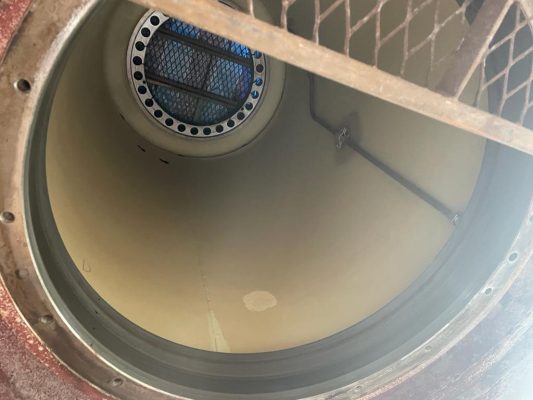

During the Lunar New year 2023, one of our client need to conduct 3D measurements and repair on both PORT and STBD Azimuth thruster’s steering tube bearing housing onboard a vessel.

Both bearing housings needed to be machined to specific dimensions to accommodate crimp fittings of sleeves. The sleeves were cooled to -60 degrees Celsius, while the bearing housing was heated to 90 degrees Celsius before the installation of the cold sleeves. Subsequently, the inner diameter of the sleeves required machining to achieve the necessary dimensions.

Solution

Following a thorough site inspection by our metrology team, we selected our newly acquired API Radian laser tracker for its portability, enabling efficient mounting over the bearing housing to extract pre- and post-machining dimensions.

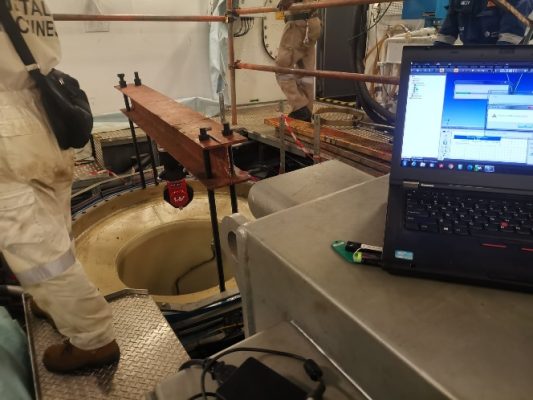

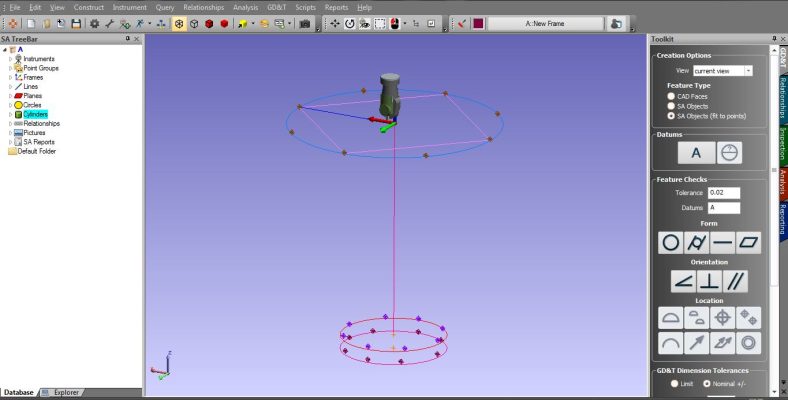

- Using API Radian laser tracker in an inverted position for measurements via Spatial Analyzer software

With modifications to our portable boring equipment, we successfully machined both the internal diameter and the top mounting flange in a single setup.

- Portable boring machine conducting machining on the thruster mounting flange and bearing housing

The API Radian laser tracker played a crucial role throughout this project, checking the setup of the portable boring machine and conducting multiple interim and final post-machining surveys.

Benefits

Utilizing the API laser tracker allowed our client to visualize the GD&T in a 3D format, facilitating informed decision-making on datum settings for machining. By performing facing of the top mounting flanges and boring of the housing in a single setup, we eliminated multiple setup times and achieved tight perpendicularity tolerances.

With a robust team of technicians and a large inventory of equipment, we were able to deploy additional resources swiftly, ensuring we cut down on critical paths and maintained the client’s project timeline.