Case Studies

The rudder system is one of the crucial components for a vessel. A semi-spade rudder is supported by a horn which consists of a rudder blade with a pintle and…

We were approached to service a critical component of a diving vessel—the diving bell trunk. This short man-way connects the entry locks (wet pots) to the diving bell, allowing divers…

A critical compressor system at a refinery began logging an increasing running temperature trend, specifically showing excessive wear on the inter-connecting shaft between the compressor and gearbox. The wear was…

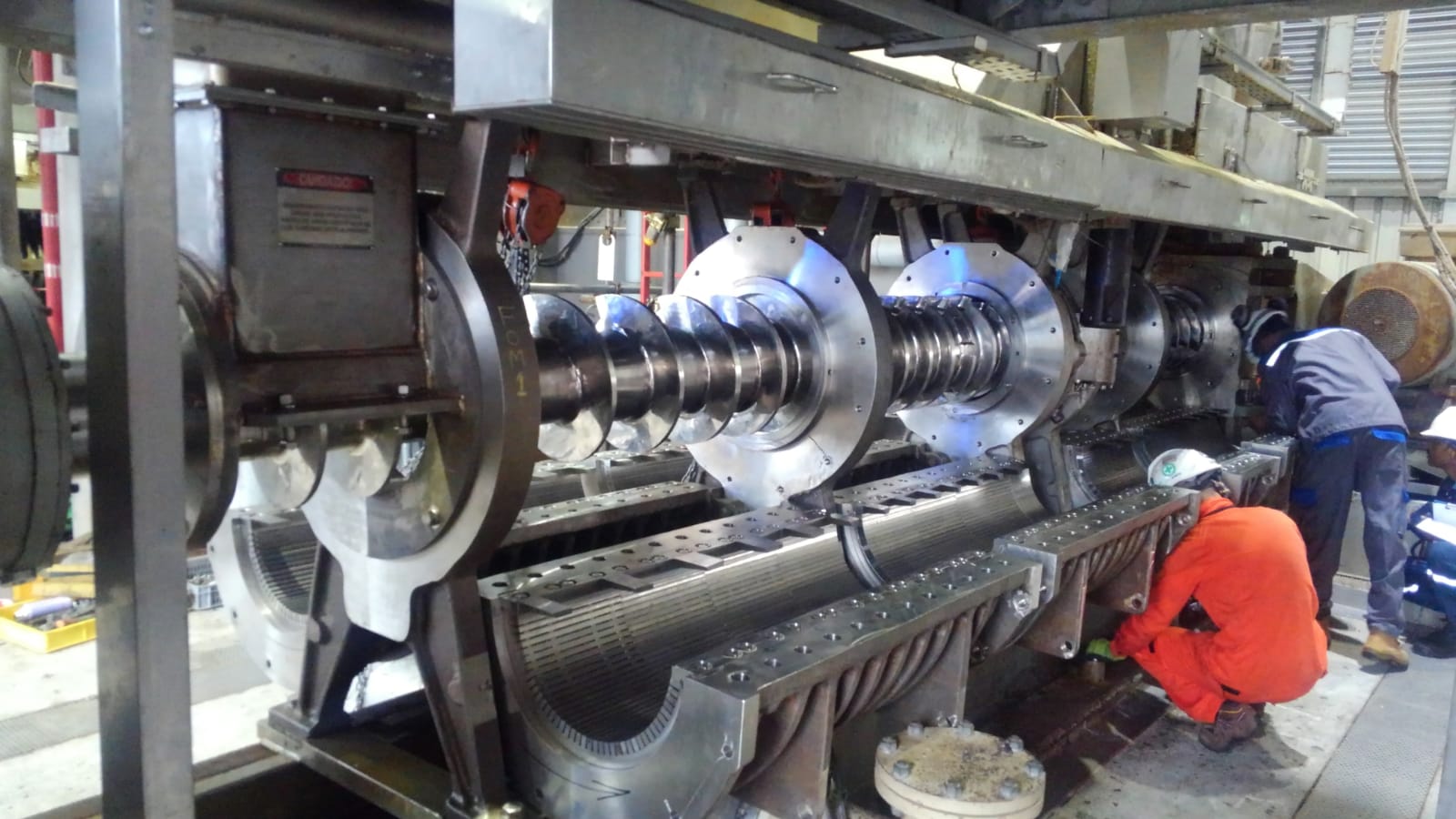

A production plant in Jurong Island, Singapore, faced recurring failures with a set of rubber extruder machines. After inspection, the machine’s OEM identified premature wear in the rotating screw and…

Following the International Convention for the Control & Management of Ships’ Ballast Water and Sediments (2004), which took effect on September 8, 2017, ships must treat their ballast water to…

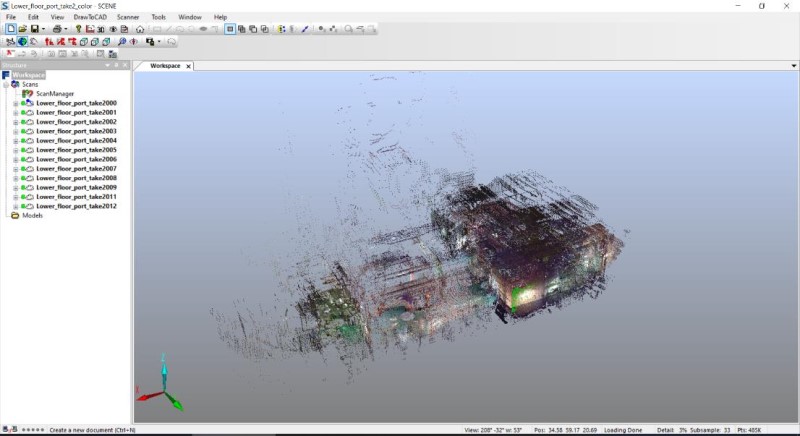

A refinery needed to machine down the compressor foundation to install compensators. To accurately determine the required machining heights of each pad, the centerline of the auxiliary engine needed to…

A client has a cable reel assembly that consists of two winged holders and a grooved wheel that functions as pulley for a cable reel system on a machine. Due to material degrading over the years, one of the winged piece snapped as shown in the picture…

A vessel docked in local (Singapore) yard was in need to change its damaged rudder stock urgently. To proceed with the replacement, data collection of dimensions and alignment of existing rudder sub-assembly (rudder blade, rudder neck and rudder horn pintle) is necessary before carrying out new rudder stock installation deliver from Europe…

A winch manufacturer was seeking for solutions to enlarge and deepen bolt holes on its supplied turret riser winch to increase the permissible heave in torque by request from the turret designer. As the winch is already housed on board an operating FPSO at…

Metal Machines received an enquiry from a client located in Malaysia to conduct onsite machining on one of the renewed ball mill’s bearing mounting flangesUpon studying the engineering drawing for the GD&T requirement, we realise this is not a straight forward machining task…