Case Studies

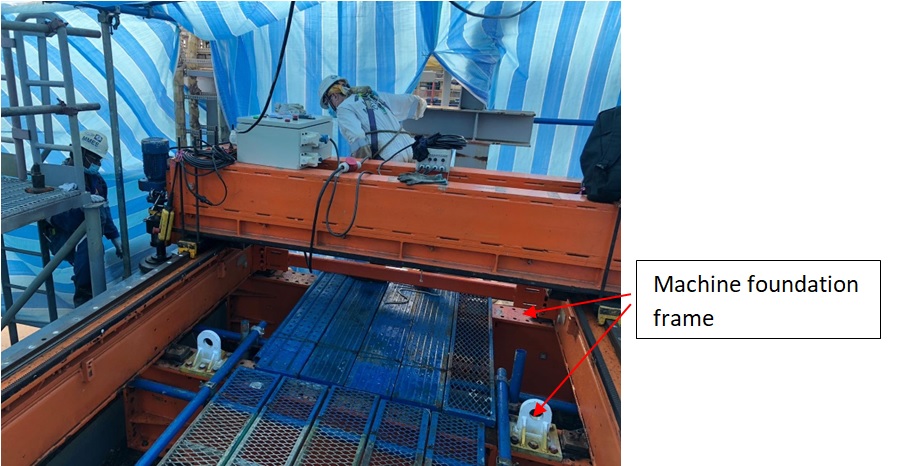

We were approached through an online enquiry by a global ship management company seeking to modify their auxiliary engine base. The original base was designed with Chockfast resin, but the…

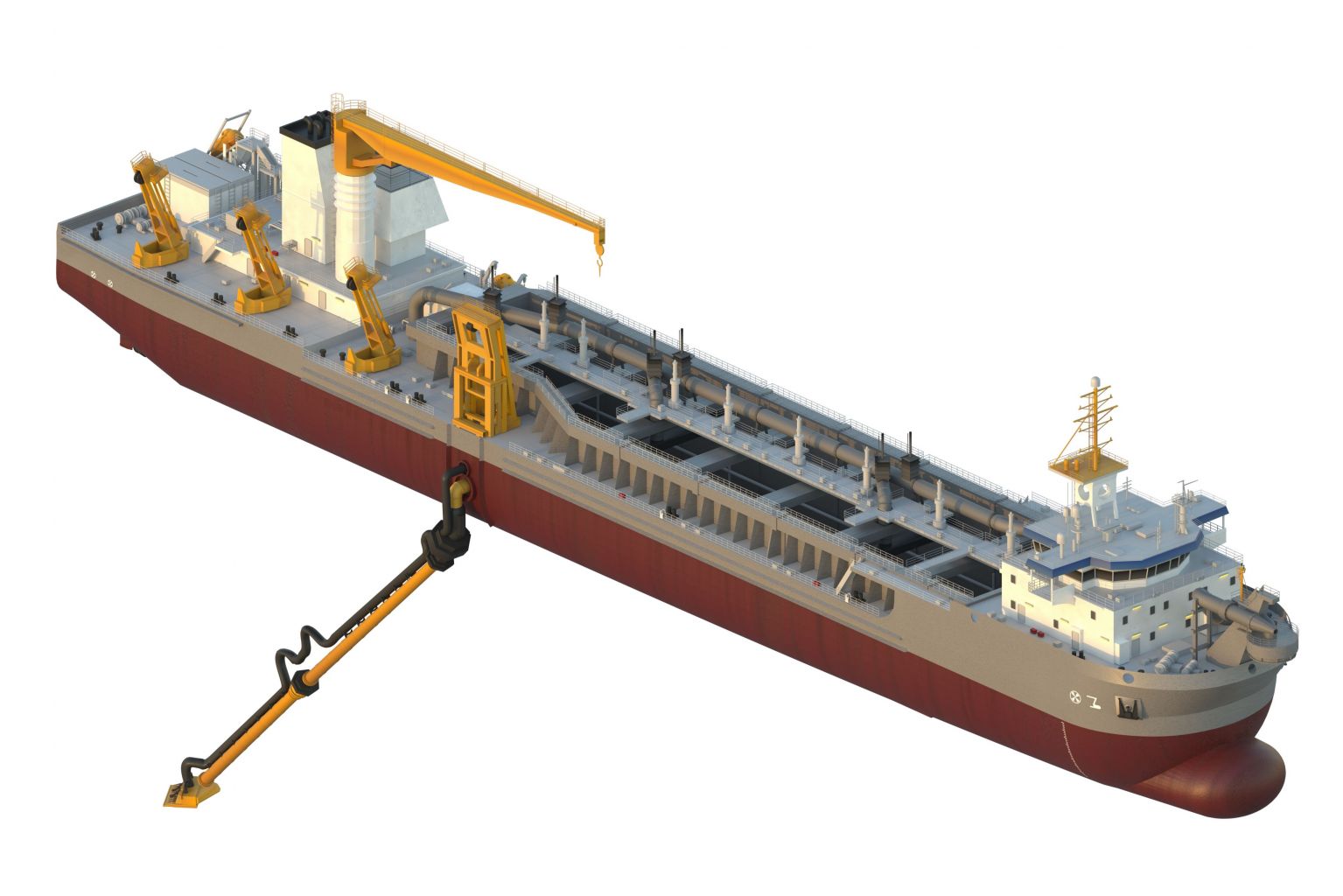

Repairing a dredger vessel presents a complex and extensive scope of work due to the unique demands on its machinery, hull, and onboard systems. The specific repairs required depend on…

Our client required In-Situ machining on a push down column structure for a wind turbine installation vessel. The primary function of these 20-meter-long push down columns is to stabilize the…

Our client required in-situ machining on a cargo elevator structure used within a patented load transfer system on wind turbine installation vessels. Due to the massive size of the structure…

During the Lunar New year 2023, one of our client need to conduct 3D measurements and repair on both PORT and STBD Azimuth thruster’s steering tube bearing housing onboard a…

Our client required precision in-situ machining on a semi-submersible Floating Production Unit (FPU) located in the Gulf of Mexico. The FPU, illustrated in Figure 1, consists of 10 riser systems,…

During the height of the COVID-19 pandemic, many companies sought to improve their operational workflows. One of our long-term clients approached us for assistance in relocating a massive lathe machine…

A subsea equipment manufacturer needs support from Coordinate Measuring Machine (CMM) to provide the Geometric Dimension & Tolerance (GD&T) for machining and assembly of a critical component. The component has…

Each in-situ machining project presents unique challenges based on site conditions, such as limited access, concurrent activities, lack of lifting equipment, and structural fabrication tolerances. These challenges require unconventional thinking…

During the COVID-19 lockdown in Singapore, shipyard operations were halted as workers were restricted to their dormitories. One of our clients urgently needed to dock a vessel for critical repairs…