Customer's Challenge

A refinery needed to machine down the compressor foundation to install compensators. To accurately determine the required machining heights of each pad, the centerline of the auxiliary engine needed to be established precisely. However, the confined space in the engine room made it challenging for conventional geometric alignment instruments to provide accurate measurements, and it also limited the range of suitable machining equipment.

Solution

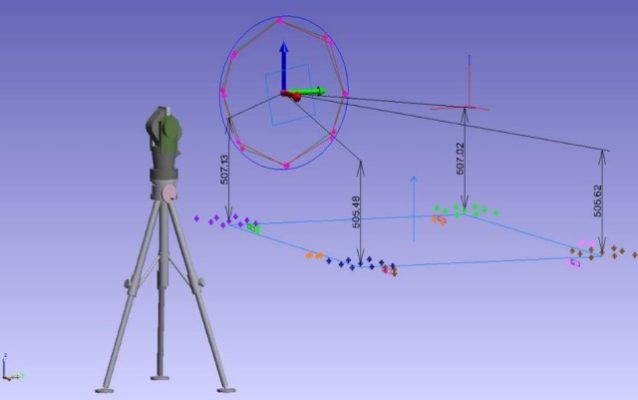

To overcome these challenges, we deployed the API laser tracker due to its portability and battery-operated capability, ideal for use in restrictive spaces. By using SpatialAnalyzer software, we collected precise 3D measurement data to establish the best-fit centerline and horizontal plane of the auxiliary engine. This allowed us to accurately measure the distances between individual pads and the horizontal center plane, identifying the amount of material that needed to be removed from each pad to accommodate the compensators.

Benefits

The API laser tracker is a high-precision 3D measurement instrument capable of capturing extensive dimensional data with accuracy. This allowed us to gather multiple data points, providing a clear overview of the machinery’s condition and enabling the client to devise optimal engineering strategies swiftly.

With the aid of our customizable in-situ machining equipment, we were able to offer flexible options tailored to the client’s lead time and precision requirements. In just 46 hours, we completed the project, including four survey rounds, milling the four seating faces, drilling, tapping, and spot facing. The result was a faster and more efficient process, delivering accurate results within a tight timeframe.