With years of experience in machine customization, we offer comprehensive engineering turnkey solutions and advanced metrology services to clients across industries such as transportation, tyre plants, equipment manufacturing, and electronic contract manufacturing. Our expertise ensures precision, efficiency, and optimal performance in every project.

Our Key Services:

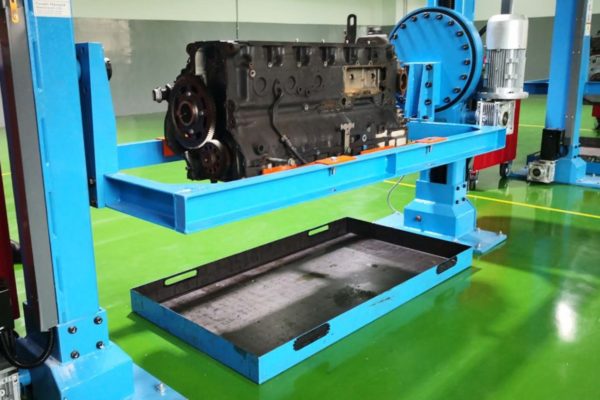

- Automotive Engine Jig Design & Commissioning for Heavy Vehicle MRO

We specialize in the design, manufacturing, and commissioning of custom jigs tailored for heavy vehicle maintenance and repair operations, improving efficiency and precision in automotive engine work. - Robot Casing Scanning & Modification

Using a Faro Edge Arm with a laser line probe, we conduct accurate scanning and modeling for robot casings, enabling modification and improvement for enhanced performance. - Signal Rail Dimension Scanning for CAD-to-Part Comparison

We utilize the SLP500 with Tomelleria Space Arm for precise dimension scanning of signal rails, ensuring accurate CAD-to-part comparison for quality control. - Custom-Built In-Situ Radial CNC Machine for Journal Bearing Pads

We designed and built an in-situ radial CNC machine to machine journal bearing pad pockets within the center hub of the world’s largest Ferris wheel, delivering high-precision machining for unique applications. - 3D Measurement of Rubber Extruder Alignment

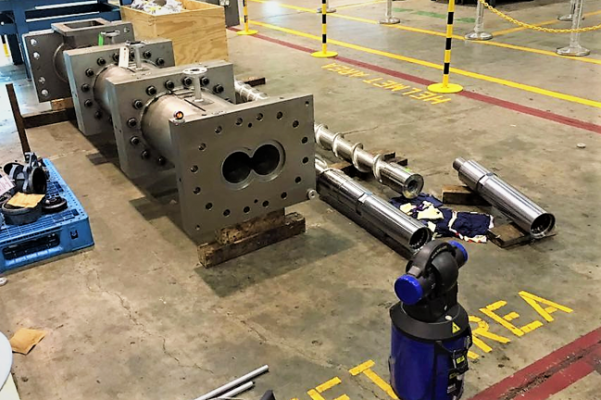

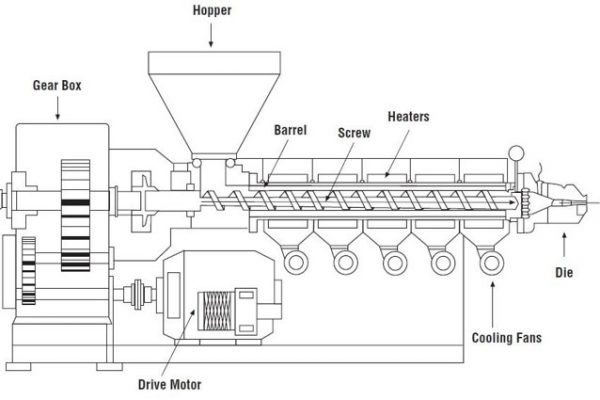

Using the Faro Laser Tracker, we perform 3D measurements to check the screw straightness and ensure perfect alignment between the screw and gearbox in rubber extruders. This method provides more accuracy compared to conventional 2D laser measurement, with live measurement readings captured for analysis. - First Article Inspection & Jig Calibration

We conduct first article inspections and jig calibration using FARO portable CMM arms and laser trackers. This service includes ensuring the product reaches 25°C for 8 hours before inspection to ensure stable measurements.

By leveraging cutting-edge technology such as Faro Laser Trackers, SLP500, and Tomelleria Space Arms, we ensure that our clients receive the highest levels of precision and reliability in their manufacturing processes.