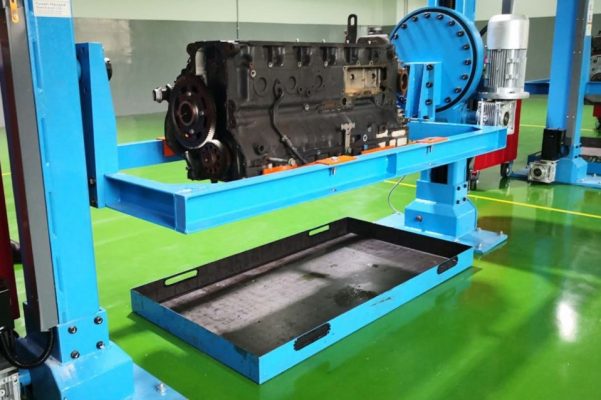

At Metal Machines, we specialize in the design and manufacture of custom servicing jigs tailored to the unique needs of the automotive and marine engine industries. Our jigs are developed based on direct feedback from workshop technicians to address common challenges and enhance productivity in engine servicing processes.

Key Features of Our Engine Servicing Jigs:

- 360° rotation and secure positioning:

The engine can be rotated and secured at any angle for easy access during servicing. - Adjustable working height:

Jigs can be adjusted up to 2 meters to accommodate technicians of all heights. - Diagonal engine securing:

Facilitates top overhaul and connecting rod removal with ease. - Enhanced safety:

Equipped with multiple limit switches and a braking mechanism for improved operational safety.

Client Testimonial:

“Metal Machines listened to our engineering needs and transformed them into 3D CAD drawings, helping us visualize how the jig would improve our workflow. They even interviewed our technicians to understand their challenges and incorporated ergonomic factors into the design!”

— Engineering Manager, Goldbell Engineering Pte Ltd