Reconditioning hydro turbines and wind mills can present significant logistical challenges due to their remote locations and the difficulty of dismantling large components. In-situ services offer a cost-effective solution by bringing portable machining equipment and advanced metrology instruments directly to the site, ensuring minimal downtime and eliminating the need for complex transportation.

In-Situ Machining for Wind Mills

- Machining of Wind Mill Columns

Using circular milling machines, we can resurface the connecting flange surfaces on wind mill columns to ensure optimal alignment and structural integrity.

Hydro Turbine Refurbishment Services

Stay Ring & Widget Gate Refurbishment

Both the upper and lower stay rings of hydro turbines, as well as widget gates, can be reconditioned on-site. Our expert team uses the Climax BB5000 for precise boring and milling tasks:

- Boring of Widget Gate Bushings

with the Climax BB5000 ensures proper fit and function. - Milling of Lower Stay Rings

is performed with circular milling machines to restore surface flatness and alignment.

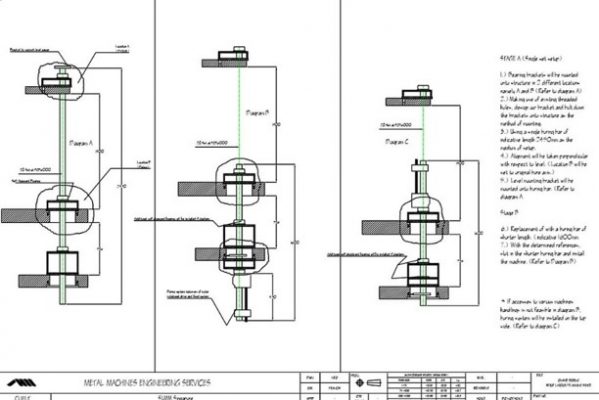

Machine Setup Procedures

We provide detailed machine setup procedures, including setup drawings for equipment like the Climax BB5000, ensuring precision and accuracy during reconditioning.

Our circular milling machines are set up to achieve flawless flatness and smooth operation, helping extend the life of these critical components.

With in-situ services, we bring high-precision machining and measurement directly to remote locations, helping minimize equipment downtime and reduce the logistics involved in sending components off-site.