Machining on Wind Turbine Installation Vessel

April 10,2023

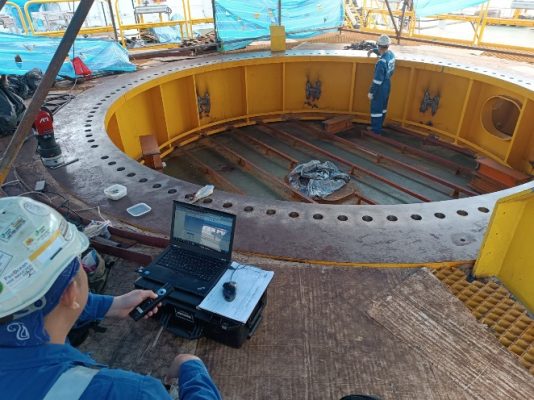

Our team has completed another repeat project on a wind mill installation vessel. A specially modified circular facing machine was used to mill off the 2 x diameter 6500mm x 600mm wide sea fastening grillage flange surfaces.

The machining scope also include drilling and spot facing of 220 x diameter 68mm holes through the 100mm thick flanges using extra-long series broach cutter.

The surface runout, PCD and holes are checked and marked using our API laser tracker to ensure the accuracy achieved.